|

CaterpillarArticulated truck MDI was involved in the concept and 3D surface development for the cab, fornt and rear hoods and front body work. The two upper images are production vehicle shots. The lower image is the original concept rendering executed in Photoshop. This design was a bit of a breakthrough for Caterpillar in the use of plastics in the body design to achieve the complex curvature of the front and rear hoods. The extreme slope of the front hood provides excellent visibility for safe maneuvering on job sites. The engine cooling package is relocated to the rear of the cab to make the sloped hood possible. |

||||||||||||

|

|||||||||||||

Composite structure - wheel loader cab This particular Caterpillar project was a special research and development program exploring the potential for composite material structures for construction equipment cab manufacturing. Based on our concept sketches and utilizing a 3D computer model for the steel ROPS (roll-over protective structure) provided by Caterpillar enginnering, the body panels, composite 'A' pillars and glass surfaces were surface modeled using Alias software. From this CAD surface data, a full size mock-up/prototype was created. |

|||||||||||||

|

|

||||||||||||

|

|||||||||||||

|

|||||||||||||

CS series Vibratory Soil Compactor Design of the 600 series plastic hood and steel drum yoke. Photoshop concept illustration. Production model soil compactor. Alias 3D surfaces. |

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

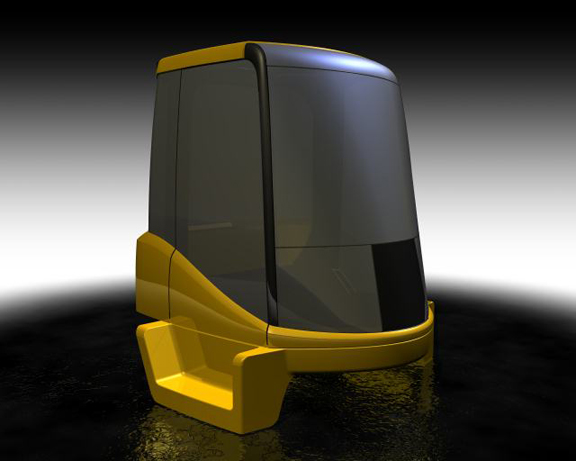

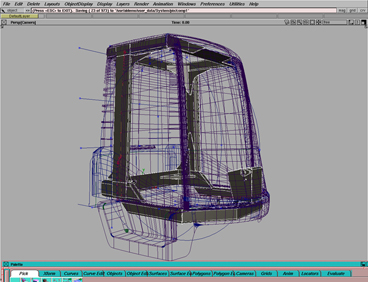

Off-highway truck concept |

|||||||||||||

|

|||||||||||||

| home | |||||||||||||